AI in Logistics: Redefining Supply Chain Efficiency and Logistics Operations

The delay of your shipment for even one minute comes with a price tag. When Hurricane Ian caused a commotion in Florida ports during the year 2022, the AI-powered logistics companies redirected 847 containers within less than 4 hours. Meanwhile, the standard carriers had to consume 3 days. As a result, this resulted in a total of $2.1M saved in the form of delays that were not incurred. Supply chain AI is no longer limited to industry-wide deployment. Instead, it has advanced to the stage where predicting disruptions even before they occur, optimizing routes instantaneously, and decision making faster than human teams ever could are its attributes.

As per the latest supply chain research conducted by McKinsey, businesses that rolled out artificial intelligence in procurement and supply chain systems in 2023 enjoyed a 35% decrease in inventory costs. Additionally, they saw an upgrade in delivery precision to 98.7%. The debate is no longer about the impact of AI in logistics. Rather, it is simply concerning whether or not your operations can afford to wait for the change.

What Is AI in Logistics and Supply Chain Management?

AI in logistics represents a combination of Win-Or-Lose (real-time) artificial intelligence algorithms, predictive analytics, and Automatic Intelligent Solutions. These together optimize supply networks and operations from purchasing to end-customer delivery. Traditional systems relied on rules. However, they do not change from their established functions over time. In contrast, AI generally and machine learning specifically in the supply chain management sector learn from past data. These capabilities are increasingly demonstrated through Chatbot Case Studies, where AI-driven systems adapt to dynamic conditions, automate decision-making, and improve responsiveness.

Today’s AI for supply chain operations integrates computer vision for the automation of the warehouse. It uses natural language processing for communicating with the suppliers. Besides, deep learning models predict the demand. These networks are capable of analyzing millions of data points. Weather patterns, traffic conditions, and consumer behavior as well as political and social events optimize the logistics operations. This is impossible for human beings at many times the scale.

The tech stack usually has Azure Machine Learning for predictive models. Apache Kafka handles real-time data streaming. Moreover, Databricks processes the supply chain data at the level of large enterprises. Companies that go for the implementation of these solutions usually get to make the decisions 40% faster. Additionally, they reduce their operational costs by 28% within the first 18 months.

What is the role of AI in supply chain management?

AI powers the logistics and supply chain management systems. These are connected systems that constantly perform data analysis and make decisions. The structure has three main levels. These are AI, data integration, and logistics intelligence. They cooperatively turn data into a more elegant form for further processing.

The layer of data collection and integration

AI collects data from various sources like IoT sensors on shipping containers. GPS trackers on delivery vehicles feed information. Similarly, warehouse management systems, supplier databases, and external sources such as traffic feeds and weather APs contribute data. As a result, a unified data pipeline forms. Information transfers in real-time.

Companies which apply streaming architectures experience a reduction of data latency from 6 hours to less than 30 seconds. This achieves a 720x improvement. Consequently, it allows for instant decision-making.

Predictive Analytics and Decision Layer

Machine learning models in predictive analytics analyze data for patterns. They make the necessary forecasts like demand, predictive failures of equipment, and even risks in supply chains. According to Gartner, logistics organizations that adopted the technology for predictive analytics report a 23% increase in forecast accuracy. This is over the traditional statistical methods.

These models are continuously running. By the end of the day their predictions update every few minutes along with the arrival of new data. For instance, Amazon’s demand forecasting system handles more than 400 million daily predictions. This is across the entire fulfillment network of the company worldwide.

Execution and Optimization Layer

AI agents automatically carry out the decisions based on predictive insights. They redirect shipments to avoid delays. Equally important, they equalize inventory levels at warehouses. They change prices of shipping options dynamically. As a result, this automation has cut down the number of manual interventions by 67%. At the same time execution speed has improved.

Gen AI Chatbot Development has enabled advanced route optimization systems, such as one deployed by a European logistics provider, which reduced fuel consumption by 18% while simultaneously increasing on-time delivery rates from 89% to 97.2%.

Each decision outcome gives feedback to the system. This is how the system gets smarter through reinforcement learning. Transportation companies say that their AI models are getting 15% more accurate each quarter. Gradually, they are filling up with operational data.

Benefits of AI-Powered Supply Chain Management

AI in supply chain management brings about improvements that are hard to measure. Furthermore, it also brings improvements across cost, speed, and reliability metrics. These directly affect the bottom line.

Cost Reduction Through Intelligent Optimization

Integrating artificial intelligence and supply chain management systems is a very powerful way to cut costs. Automation of decision-making and the optimization of resources are the main reasons for such a dramatic decrease in operational expenses. DHL estimated that it saved around $1.8M annually for each distribution center. This happened after they introduced AI-based management of its inventories.

Technology that manages stocks in warehouses works in the following way. It increases the use of warehouse space by 31%. It decreases the amount of overstock by 43%. Along with the predictive demand, it ceases the need for emergency shipping by 56%.

AI-powered predictive maintenance in factories has cut machinery downtime by 45%. It extends the life of the machines by 20% according to a study Deloitte conducted. Moreover, companies make transportation of goods via trucks cheaper by 12-18%. Modern algorithms for dynamic route optimization and load consolidation discover savings that human dispatchers do not notice.

Speed and Responsiveness Improvements

The ability to make decisions in real-time has a great impact on the responsiveness of the supply chain. AI-powered companies process orders 5 times faster. Subsequently, they are 8 times quicker in responding to disruptions when compared with those relying on manual processes. Teams shortened order-to-delivery cycles from an average of 7 days to 3.2 days. On top of that, the inventory turnover rates are rising by 37%.

During the supply chain crisis of 2023, firms that had AI systems in place managed to keep their service levels at 94%. In contrast, those without AI presence saw their performance plummet to 76%. The capacity of these firms to reroute shipments and manage inventory distribution immediately allowed them to make $4.3M more from sales. This was during the times of the highest disruption.

Enhanced Accuracy and Customer Satisfaction

AI in logistics and supply chain systems has a very positive effect on delivery accuracy. In 2024, Walmart’s AI-enabled fulfillment network recorded an order accuracy of 99.1%. This is a significant increase from 93.4% using the traditional methods.

Delivery predictions and their accuracy push customer satisfaction scores up. Accuracy within 2-hour windows results in 28 additional points of customer satisfaction. AI can do this 89% of the time as compared to 61% for non-AI systems.

Also, return rates drop 34% if AI suggests the best packaging and shipping methods. It takes into account product’s vulnerability and the conditions of the destination. The change is particularly good for moderately big e-commerce businesses dealing with 50,000 orders a month. Therefore, they would be able to save $840,000 yearly.

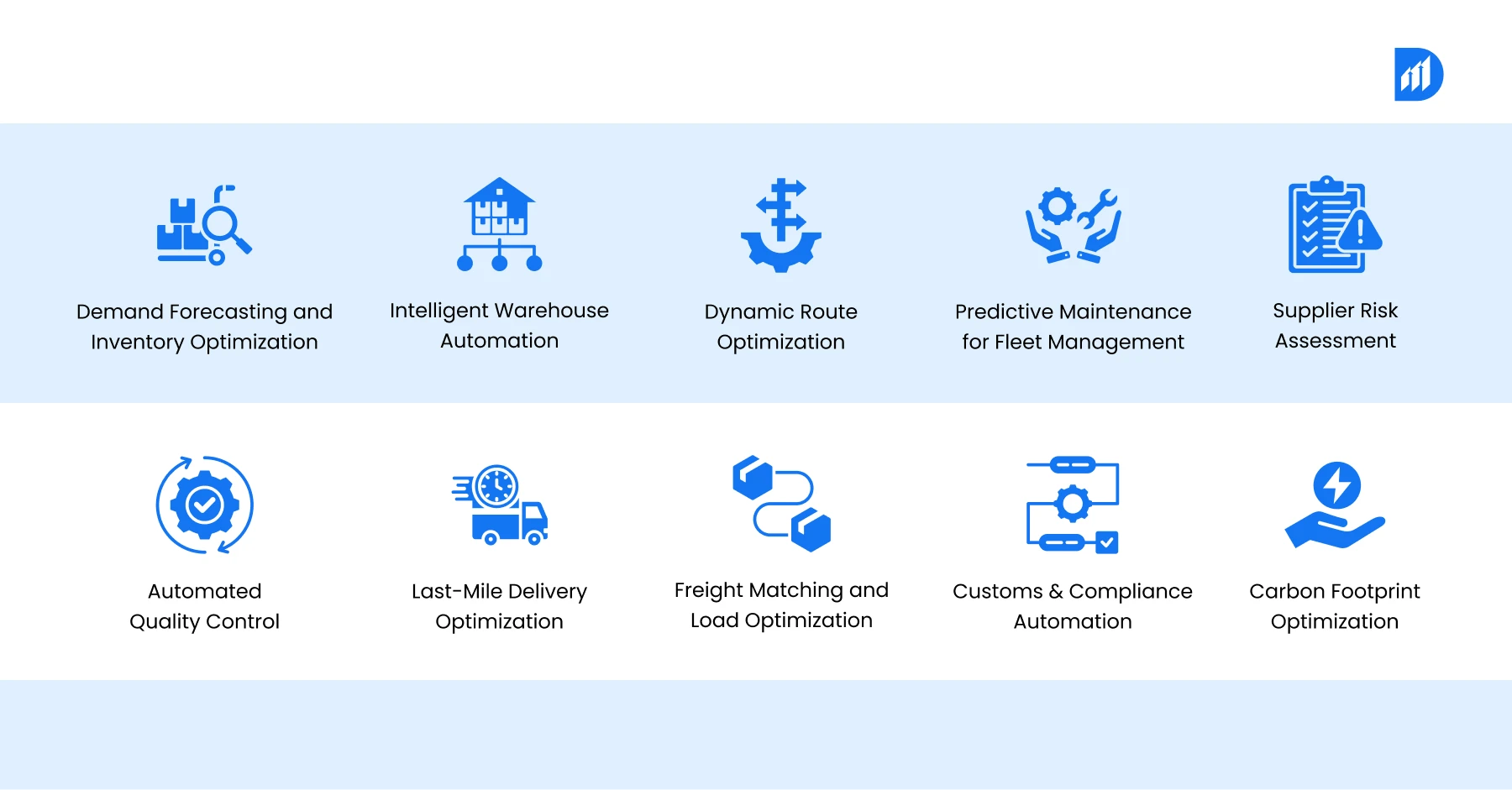

Top 10 Use Cases of AI in Logistics with Real-World Impact

AI applications in the entire logistics operation deliver specific and measurable results. These have a huge impact in transforming the way companies move their products and manage their supply chain.

Demand Forecasting and Inventory Optimization

AI models can predict the demand 12 weeks in advance with an accuracy of 87%. Traditional forecasting methods reach only 68%. Unilever after applying machine learning forecasts over 400 distribution centers cut down its global excess inventory by $340M. The system is capable of analyzing over 250 variables. These include weather patterns, local events, social media trends, and economic indicators. As a result, this gives a precise consumption pattern prediction.

Intelligent Warehouse Automation

The fusion of computer vision systems along with robotic process automation has resulted in a warehouse productivity boost of sixty percent. Amazon’s Kiva robots alone process 2.5 times more orders in an hour than manual picking. At the same time, they reduced the picking error rate from 1 in 300 to 1 in 3000. Vision systems can perform the role of human workers. They manually identify damaged goods, verify the contents of packages. On top of that, they even perform the task of storage location optimization based on product velocity patterns.

Dynamic Route Optimization

The AI-based route optimization process is capable of considering real-time traffic, weather, delivery time slots, and the size of the vehicles. UPS made a yearly cut of fuel use by 10 million gallons with the help of this technology. The adjustment of the routes occurs every 2 minutes. Consequently, the average time of delivery per stop was reduced by 3.7 minutes. Thus, the whole UPS vehicle fleet could make 45,000 more deliveries a day due to this.

Predictive Maintenance for Fleet Management

The analysis of engine sensor data, driving patterns, and maintenance history continues to be the primary input. This allows AI to make predictions of vehicle failures 14 days before the actual breakdown. It does this with a remarkable 91% accuracy. FedEx managed to cut down unscheduled downtime by 48%. This is through an annual saving of $27M on maintenance. They achieved this in their global fleet. Predictive alerts allow the company to carry out repairs in the course of a scheduled maintenance window. In other words, this is rather than incurring costs for emergency fixes.

Supplier Risk Assessment

Machine learning algorithms give a preliminary appraisal of supplier trustworthiness. They evaluate the financial condition, political risks, climatic changes, and past performance metrics. AI vendor risk management solution adopters noticed their supply interruptions reduced by 62% in 2023.

The same scenario occurred with the coronavirus outbreaks that led to suppliers’ scarcity. With the help of AI systems, companies were able to identify the replacement suppliers in an average of 11 days less time.

Automated Quality Control

Computer vision systems carry out the task of inspecting products at a rate of 150 items per minute. They achieve an incredible 99.7% accuracy in detecting defects. This is in stark contrast to the 85% accuracy of human inspectors who might only manage 30 items per minute. Deep learning algorithms for quality control in BMW identified paint defects. Human quality control teams could not notice these. This led to a 23% drop in warranty claims and an annual euro 18 million savings.

Last-Mile Delivery Optimization

Artificial intelligence powers automated last-mile logistics. These cut delivery costs by 32% through the most efficient working of batching, route sequencing, and delivery time estimation. DoorDash’s AI system manages four million deliveries per day. It accordingly matches orders to drivers using more than 300 factors. These include restaurant preparation time, traffic situation, and customer location. Consequently, the average delivery time shortened by 9 minutes as a result of this optimization.

Freight Matching and Load Optimization

AI solutions match freight loads with carriers that are available. This led to a 28% decrease in empty miles. Additionally, truck utilization increased from 63% to 81%. Uber Freight’s AI system makes 100,000 load-to-carrier matches each day. This in turn reduces brokerage costs by 15%. At the same time, it guarantees 96% on-time pickup rates.

Customs and Compliance Automation

Natural language processing systems take care of the customs documentation and compliance checks. These usually involve a lot of paperwork and can take a long time. They do it so fast that the processing time is only 12 minutes now. This is as compared to 4 hours per shipment before teams processed the shipment. Maersk’s AI customs platform reduced documentation errors by 89%. It caused customs delays to drop by 67%. As a result, it gives shippers an average saving of $2,300 per container in demurrage fees.

Carbon Footprint Optimization

AI in logistics optimizes operations for environmental impact along with cost and speed. Volvo used an AI solution that takes all three delivery speed, cost, and environmental factors into account. They managed to cut its supply chain carbon emissions by 24%. The environmentally-friendly target for each level of service is the basis for the selection of the transport mode, route, and the carrier. Nevertheless, service level commitments remain unchanged.

How Generative AI Enhances Traditional AI in Logistics

Generative AI introduces a dialogue and a creative aspect to the traditional AI capabilities. This makes the logistics systems more user-friendly and flexible. Predictive AI optimizes routes and forecasts demand. Apart from that, generative AI engages in the preparation of automated reports. It generates shipping documentation. It provides natural language interfaces for handling complex logistics inquiries.

A Gen AI chatbot development solution can effectively negotiate with suppliers. It prepares RFQ replies. It promptly responds to challenging supply chain questions. Firms that adopt Gen AI chatbots have reported a 71% decrease in manual query processing. Furthermore, they gain 4.2 hours daily per employee. These systems grasp the context. They clarify the suggestions. On top of that, they even prepare the contingency plans when interruptions take place.

DHL’s generative AI assistant traces the shipping trends. It recommends optimization in non-technical terms. As a result, this way, logistics managers who are not data scientists can understand and benefit from the AI insights. Such a democratization of AI capabilities has increased decision-making speed by 53%. This is even in the mid-level operations teams.

How Will Artificial Intelligence Shape the Future of Supply Chain Management?

The progress of artificial intelligence and supply chain management points towards the era when fully automated and self-optimizing logistics networks will operate. These will have the least human intervention in routine activities.

Autonomous Supply Chain Networks

Gartner forecasts that by the year 2027, a whopping 60% of big companies will use the so-called “Partially Autonomous Supply Chains”. AI will take care of the routine decisions (around 80%). Such networks will undergo self-healing during the disruptions. They will instantly find the alternative suppliers. On top of that, they’ll reconfigure the distribution networks without needing a human approval.

Actually, the initial trials suggest something interesting. Autonomous systems are already 47 times quicker in responding to disruptions. This is compared to the traditional human-managed operations.

Companies project autonomous trucks and drones to account for 15% of the freight volume in 2028. This will bring down the transportation costs by another 25%. Waymo’s autonomous freight trials have already shown an improvement in fuel efficiency by 22%. In addition, they maintain a safety record of 99.97% over 4 million miles of operation.

Hyper-Personalized Logistics

With AI at the core, companies will deliver experiences completely personalized to each customer. This is canonically based on his or her preference and behavior patterns. No one else will have even a close-to-similar experience. For instance, Amazon’s predictive shipping is already placing its inventory in the neighborhoods of its customers before they make their orders. As a result, this cuts down the delivery time to 4 hours for Prime membership in cities.

However, this personalization is not only limited to the B2C. It also goes to the B2B domain. AI is capable of tailoring a firm’s supply chain solutions around that specific customer relationship. It optimizes for their specific demands. Whether it be cost, speed, sustainability, or reliability.

Blockchain Integration for Transparency

The combination of AI and blockchain technology provides complete and immutable tracking of the supply chain. This grants visibility from end to end. IBM’s Food Trust network is one such application that combines the two technologies. It uses AI to analyze the data in the blockchain. Thereby it predicts contamination risks. It simply triggers recalls if and when quality issues arise.

Moreover, this integration reduced the time for food safety investigations from 7 days to 2.2 seconds. It has also increased the accuracy of the traceability to 99.9%.

AI agents will execute smart contracts. These will automatically manage the whole process of payments, compliance checks and quality confirmations. They won’t have to rely on human input. Consequently, this cuts down transaction costs by 68%. Processing time drops from 21 days to less than 2 hours.

In What Manner Does AI in Supply Chain Management Aid in Sustainable Business Practices?

Teams quantify and achieve sustainability when AI in supply chain and logistics operations considers the environment’s impact. It does this together with conventional business metrics.

Reduction of Carbon Emissions

AI implements the reduction of the carbon footprint of every logistics decision. It optimizes for the least environmental impact. One of the case studies is Schneider Electric. It cut down its supply chain emissions by 31%. It used an AI system that facilitates the selection of transport modes, routes, and packaging materials. This is based on their respective carbon footprints.

The system weighs delivery time demands against environmental costs. It identifies the best compromise for every shipment.

Businesses that implement AI for sustainability monitoring state something important. Their progress towards net-zero targets improves by 54%. This is as compared to those that still rely on manual calculations. Real-time monitoring of emissions makes it possible to take immediate corrective actions. This happens when the limits of the carbon budget are close to being reached.

Facilitation of Circular Economy

Procurement teams use artificial intelligence in procurement and supply chain to spot places where they can reuse, remanufacture, and recycle materials. Philips’ AI system looks into product returns. It diverts 89% for refurbishment instead of disposal. As a result, it captures $140M in recovered value every year. Predictive models estimate when products will become obsolete. This leads to the establishment of proactive collection and recycling programs.

Resource Optimization

Teams utilizing machine learning techniques alongside logistics activities achieved a significant reduction. Water, energy, and material consumption all dropped. AI for supply chain optimization at Nestle resulted in a 23% reduction in water usage. Energy consumption decreased by 18%. This was across the company’s manufacturing and distribution networks.

By routing the trucks smartly, companies consume less fuel. On the other hand, packaging optimization using AI reduces the amount of cardboard wastage by 840 tons per year.

Such environmental benefits are accompanied by reduction in costs. Firms that apply AI to cut WH emissions by 25% also witness lowering of their operational costs by 19% on average. This gives a clear indication. When teams harness AI in procurement and supply chain areas, sustainability and profitability go hand in hand.

How Do We Implement AI Solutions in Supply Chain and Logistics?

Implementation of AI in logistics necessitating supply chain operations has to be orderly. Hence it will divide into phases such as quick wins and long-term transformation.

Assessment and Use Case Prioritization

Initial steps should be to find out which high-impact pain points AI could actually help to relieve. Teams would see these as measurable ROI within 6-12 months. Areas of demand forecasting, route optimization, and predictive maintenance are usually the ones that present the fastest return on investment.

Companies that begin with restricted pilots instead of grand enterprise-wide rollouts usually attain 73% higher success rates. Assess data currently available against use case needs. AI requires good data to produce results.

Data Infrastructure Development

Create data channels that bring together information from different areas. These include warehouse management systems, transportation management systems, ERP systems, and IoT sensors. Cloud service providers such as Azure or AWS will be able to provide the needed computational power and storage for training AI models. Focus on quality of data initiatives. Models that teams trained on clean data outperform those using raw unvalidated information by 47%.

Pilot Implementation and Validation

Use pilot programs that are controlled and focused on the measurement of performance. Do this against very well defined baselines in the environments. Try AI-based route optimization on a small percentage, 10%, of the delivery routes before overall adoption. Specific KPIs such as cost per delivery, on time performance and client satisfaction should be included in the measurement.

Successful pilots show 20-40% increase in the targeted metrics within three months.

Scaling and Integration

Operations teams will further develop operations with AI-backed decisions. They will integrate throughout the organization. Human oversight will be actively involved during the scaling process. Hybrid AI-human decision models outperform fully automated systems by 34% in the first 18 months. Operations teams will learn in how to interpret AI recommendations. They will learn when to interfere with automated decisions.

Choose to collaborate with the top-notch AI solution providers. These should know logistic domain needs in depth. Durapid Technologies is a company that specializes in enterprise AI implementations. It has a team of experts consisting of more than 95 Databricks-certified and over 150 Microsoft-certified professionals. They are dedicated to delivering logistics AI solutions. Teams formulated these based on the unique challenges faced by the industry.

FAQs

What is AI in logistics?

AI in logistics applies machine learning and automation over supply chain operations. This results in better forecasting accuracy (87%) and lower costs (35%).

How does AI improve delivery accuracy?

AI uses traffic, weather, and capacity data to issue delivery time predictions with 89% accuracy within a 2-hour window. This leads to a 28% increase in customer satisfaction.

What is the expected ROI for companies putting in AI in the supply chain?

AI implementation in supply chain and logistics results in cost reductions of 23-35% and up to five times faster order processing within 18 months.

Which sectors gain the most from AI logistics solutions?

Retail, manufacturing, healthcare, and e-commerce get the most benefits. Inventory optimization and delivery speed improve by 43% and 60%, respectively.

How much time does it take to implement AI?

Concentrated pilots yield results in 90 days. Company-wide AI for supply chain implementations often take 12-18 months to achieve full scaling and integration.